How to identify whether the industrial aluminum profile is qualified?

As an aluminum profile manufacturer, let me share with you.

Aluminum profiles can be divided into raw aluminum and cooked aluminum. Raw aluminum is aluminum below 98%, which is brittle and hard and can only be found in sand casting products.

Boiled aluminum is aluminum of 98% or more. It is soft in nature and can be rolled or punched in a variety of appliances.

Contribution of industrial aluminum profiles to environmental protection

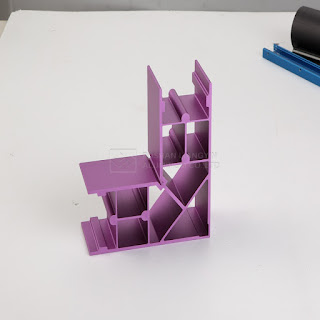

Industrial aluminum profiles, also known as industrial aluminum, are cylindrical objects with different cross sections made of extruded aluminum alloy. What is the contribution to social and environmental protection?

The so-called contribution of industrial aluminum profiles to environmental protection actually refers to the contribution of industrial aluminum profile products to environmental protection. The products customized with it do not rust, have high friction and corrosion resistance, and have no problem to use for 50 to 60 years. Examples include aluminum alloy shelves, aluminum alloy cabinets, etc. In addition to these industrial aluminum products, some environmental facilities can be customized. For example, smoking rooms and clean rooms are customized with aluminum materials. The former provides convenience for smokers and isolates the danger of second-hand smoke to non-smokers. The latter provides a clean area for special tasks.

The future of environmental protection will continue to permeate our lives and work. To have a good living and working environment, environmental protection is imperative. The application of industrial aluminum profiles is undoubtedly a contribution to environmental protection. In fact, in addition to industrial aluminum profiles and stainless steel products, they are also more environmentally friendly industrial products, just a little less cost-effective than aluminum.

Industrial aluminum profiles qualified identification skills are the following.

1. the raw material is not qualified, in the goods in the Senate some miscellaneous aluminum, scrap aluminum profiles cost greatly reduced, but it will lead to aluminum profiles chemical composition is not qualified, seriously affect the quality of aluminum profiles.

2. Aluminum profile thickness. The thickness of the aluminum profile is an important condition in relation to the meter weight of the aluminum profile, as well as the price, so the thickness is sufficient, but also a reflection of good quality.

3. Insufficient production equipment, industrial aluminum profiles in the production period need to use professional social equipment and operators need to carry out professional training, strict compliance with the relevant procedures and corresponding parameters to operate.

4. Thin oxide film thickness. The standard stipulates that the oxide film thickness of architectural aluminum profiles should not be less than 10 um. If the thickness is not enough, the surface of aluminum profiles is easy to rust and corrode. According to expert calculations, for every 1um reduction in oxide film thickness, the cost of electricity consumption per ton of profile can be reduced by at least 150 yuan. Unqualified aluminum profiles will be affected by air, rain and sunlight in the process of use, which will lead to deformation of aluminum profiles and even cause the glass to break and fall off.

评论

发表评论