Introduction of Extruded Aluminum

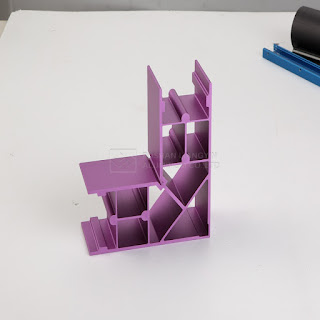

Extruded aluminum is a continuous item of lightweight aluminum, generally with a consistent profile or cross-section over its entire length. It is made forcibly a block of lightweight aluminum, called a billet, through a die opening that is smaller than the initial cross-sectional location of the billet. The extrusion procedure can be warm or cold, depending upon the type of lightweight aluminum alloy as well as the extrusion technique made use of.

Lightweight aluminum is an excellent material because it is lightweight, solid as well as rust-resistant. In its pure kind, it is soft as well as has low strength. To boost its mechanical properties, it is normally alloyed with aspects such as copper, magnesium, manganese, and also silicon. Additionally, it can be warmly treated to additional boost strength as well as ductility as well as to achieve the appropriate equilibrium.

Lightweight aluminum is the most generally used metal for extrusion molding. This steel has a one-of-a-kind mix of mechanical buildings, such as high stamina, low thickness, and great machinability. These properties are almost continuous in all temperature levels.

Aluminum is prominent for its lightweight and high toughness. Its density has to do with one-third that of steel. Depending on the quality, lightweight aluminum alloys are up to 5 times more powerful than steel. Because of this property, aluminum is widely made use of in aerospace and vehicle applications.

评论

发表评论