FoShanLiangYin Exploring the Art of Aluminum Extrusion Die Design

Aluminum extrusion is a widely used manufacturing process, particularly for producing various aluminum profiles. In this blog post, we delve into the intricacies of aluminum extrusion die design, understanding the workings of this process and its crucial steps.

Aluminium Profile Manufacturer (liangyin-alu.com)

**Fundamental Principles of Extrusion**

Extrusion involves heating a block of high-purity aluminum alloy to a suitable temperature and then using a die to squeeze out the desired cross-sectional shape. The basic principles of this process involve several key elements:

1. **Aluminum Stock Preparation**: First, high-purity aluminum alloy billets are sheared into bars of the required length.

2. **Heating**: These aluminum bars are heated to the appropriate extrusion temperature, typically between 400°C to 500°C. Heating increases the aluminum's plasticity, making it more amenable to shaping.

3. **Extrusion**: The aluminum bars are fed into an extrusion press, where one or more dies are used to extrude the desired profile. High pressure is applied to force the aluminum through the die's openings, shaping it accordingly.

4. **Cooling**: The extruded aluminum profiles are cooled, often using water, to restore their strength and hardness.

5. **Cutting and Sizing**: Finally, the profiles are cut to the required lengths and then sized to meet specific specifications.

**Liangyin Extrusion Die Design Process**

The quality and efficiency of aluminum extrusion depend on the intricacy of the extrusion die design. Here are some key steps:

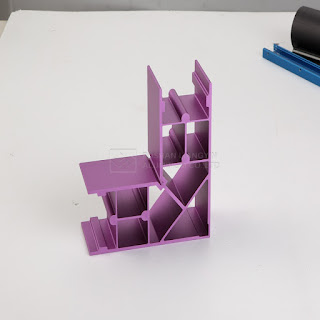

1. **Die Design**: The design of the die is critical. It must accurately reflect the desired cross-section and consider factors such as metal flow, cooling, and extrusion pressure.

2. **Selecting the Right Aluminum Alloy**: Different aluminum alloys have varying performance requirements for extrusion. Choosing the right alloy is critical to ensuring the quality of the profiles.

3. **Control of Extrusion Parameters**: Precise control over the extrusion press's temperature, pressure, and speed is essential to ensuring consistent profile quality.

4. **Quality Inspection**: The extruded profiles undergo quality inspection to verify their dimensions, appearance, and performance against specifications.

**Applications**

LiangyYin Aluminum extrusion is widely employed in various fields, including construction, automotive, electronics, aerospace, and many other industrial sectors. It is used to produce a wide range of profiles, including window frames, door frames, automotive body components, and railings, among others.

We hope this blog post helps you better understand the intricacies of aluminum extrusion die design. If you have any questions or need further information, please feel free to leave a comment.Aluminium Profile Manufacturer (liangyin-alu.com)

评论

发表评论