What are the factors that affect the thermal performance of heat sink?

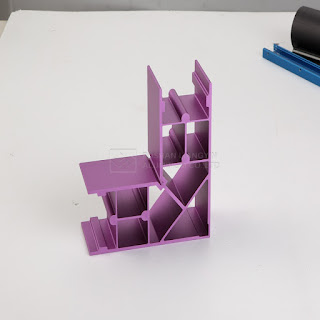

Extrusion Heat Sinks & Profiles for Cost Effective Cooling Solutions

Foshan Liangyin offers a wide variety of ultra-performance straight fin, slant fin, and pin fin extruded heat sinks. These high aspect ratio heat sinks are ideal for applications where there is adequate airflow to take optimum advantage from these designs. We also offers an array of heat sink extrusion profiles with different thermal performances, fin-to-fin spacing, lengths and heights. Extrusion profiles enable engineers to either select or start their design from a pre-tooled extrusion profile for the cooling solution.

When selecting or designing a Heat sink, the following factors must be considered.

Material

The most common Heat sink material is aluminum alloy. Aluminum alloy 1050A has one of the higher thermal conductivity values, 229 W/m-K, but has softer mechanical properties. Aluminum alloys 6060 and 6063 are commonly used and have thermal conductivity values of 166 and 201 W/m-K, respectively. these values depend on the tempered condition of the alloy.

Surface color

Radiant cooling may be an important factor in cases of low convection, such as flat finless panels with low airflow. Here, surface properties may be an important design factor. In the visible spectrum, matte black surfaces radiate more efficiently than shiny bare metal. Shiny metal surfaces have low effective emissivity due to their low surface area.

Thermal resistance

The heat flow between the semiconductor chip and the ambient air is modeled as a series of thermal flow resistances; from the core to the device enclosure, from the enclosure to the heat sink, and from the heat sink to the environment.

Heat sink efficiency

A heat sink can be thought of as a flat plate where heat flows at one end and dissipates into the surrounding fluid as it travels to the other end. As the heat flows through the fins, the thermal resistance of the heat sink that impedes the flow and the heat loss due to convection combine to lower the temperature of the fins, so the heat is transferred from the bottom of the fins to the end of the fluid.

Propagation resistance

Propagation resistance occurs when heat energy is transferred from a small area to a larger area in a substance with finite thermal conductivity. In a heat sink, this means that the heat is not evenly distributed through the bottom of the heat sink. The phenomenon of diffusion resistance manifests itself in how heat propagates from the location of the heat source and creates a large temperature gradient between the heat source and the edge of the Heat sink.

End Arrangement

A pin-fin Heat sink is a Heat sink with pins that protrude from the base. The pins can be cylindrical, oval or square. Pins are one of the more common types of heat sinks on the market today. The second type of heat sink fin arrangement is straight fins. They run the entire length of the Heat sink. A variation of the straight fin Heat sink is the cross cut Heat sink. Straight fin Heat sinks are cut periodically.

评论

发表评论