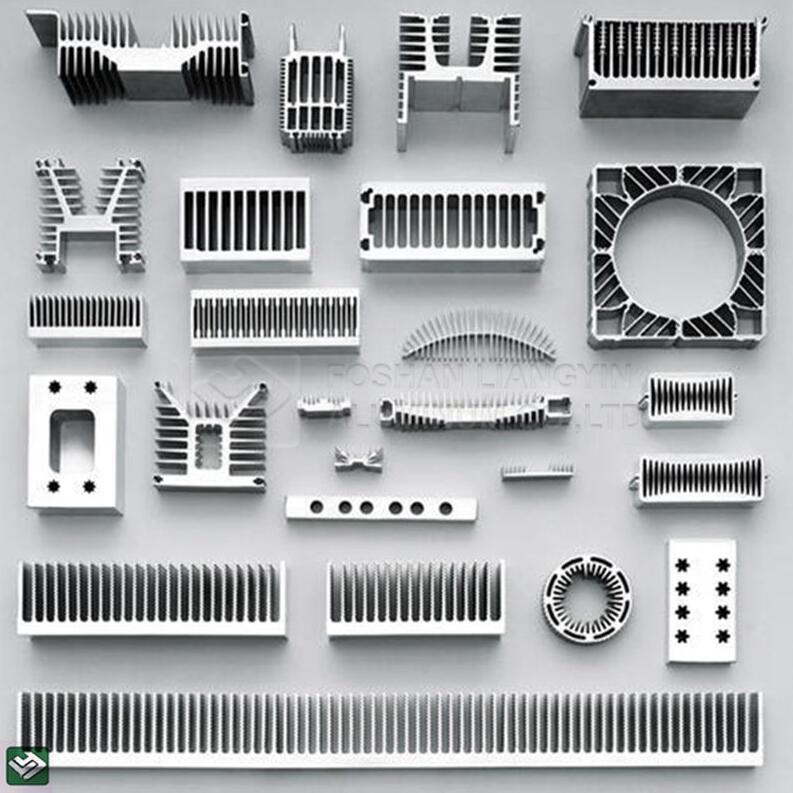

Design factors that affect the thermal performance of a heat sink

When selecting or designing a heat sink, the following factors must be considered.

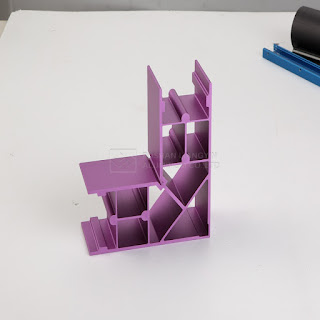

Material

The most common heat sink material is aluminum alloy. Aluminum alloy 1050A has one of the higher thermal conductivity values, 229 W/m•K, but is mechanically soft. Aluminum alloys 6060 and 6063 are commonly used and have thermal conductivity values of 166 and 201 W/m•K, respectively. These values depend on the temper of the alloy.

Heat sink efficiency

The heat sink fin can be thought of as a flat plate where heat flows at one end and is dissipated into the surrounding fluid as it travels to the other end. As heat flows through the fins, the thermal resistance of the heat sink that impedes the flow and the heat loss due to convection combine to reduce the temperature of the fins and therefore the heat transferred to the fluid from the bottom to the end of the fins.

Thermal resistance

The heat flow between the semiconductor chip and the ambient air is modeled as a series of thermal flow resistances; resistance exists from the core to the device housing, from the housing to the heat sink, and from the heat sink to the environment.

评论

发表评论