How to choose the right surface finish for machined aluminum?

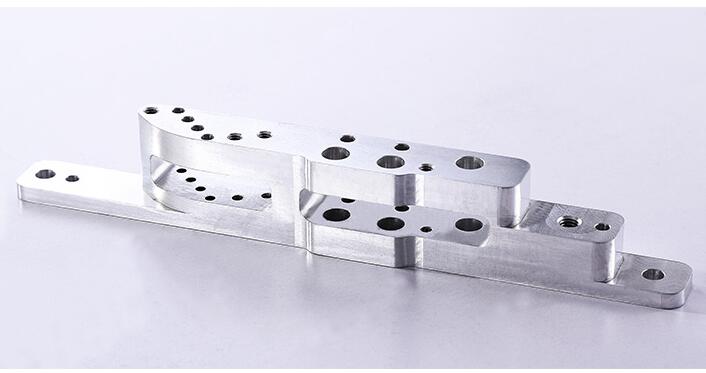

CNC machining is a traditional manufacturing process that uses a drill and turning tool to create parts by removing material from a solid block of material. The process is fast, repeatable and ideal for making parts with tight tolerances. CNC machining can be done with any material rigid enough - from plastic to metal to fiberglass - and aluminum is a popular choice among product teams.

Aluminum Grade Selection

The first step in starting your CNC aluminum machining project is choosing the right metal alloy. Each grade has its own unique set of properties and characteristics, depending on your needs. When examining the properties of aluminum, you need to consider strength, electrical conductivity, corrosion resistance, or a combination of all of these.

Two of the most common aluminum metals used in industry are 6061 and 7075 aluminum alloys. So, what is the difference between the two?

6061 Aluminum Properties

6061 is a common aluminum alloy produced through a heat treatment and drawing process. CNC machined 6061 aluminum products are widely used in industrial structures and other applications for their high strength and corrosion resistance.

With its excellent machinability, durability, unique characteristics and affordability, aluminum 6061 is the CNC machined material of choice in the manufacture of parts for various industries such as aerospace, transportation, and construction. It is widely used in CNC machine shops for 5-axis precision machining.

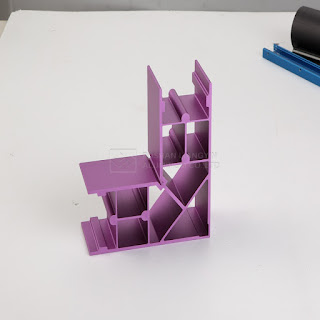

6061, also known as Alloy 61s, is one of the most common aluminum alloys for general purpose, mainly contains aluminum, magnesium and silicon, other 6061, also known as Alloy 61s, is one of the most common aluminum alloys for general purpose, containing mainly aluminum, magnesium and silicon, other metallic elements include iron, copper, chromium, zinc, manganese and titanium. It has good mechanical properties, good weldability and suitable to be extruded. 6061-T6 and 6061-T651 are tempered grades of 6061 aluminum.

Aluminum alloy 6061 properties and features:

◭ Can be heat treated

◭ Set the standard for a medium-to-high strength, lightweight, economical material

◭ Structural strength, toughness

◭ Good corrosion resistance to atmosphere and sea water

◭ Easily to be welded

◭ 6061 aluminum density: 2.7 g/cm³

◭ Tensile strength of aluminum 6061: 124-290 MPa (18.0-42.1 ksi)

◭ 6061 aluminum yield strength: ultimate yield strength of at least 240 MPa (35,000 psi)

评论

发表评论